Customer demand is our pursuit

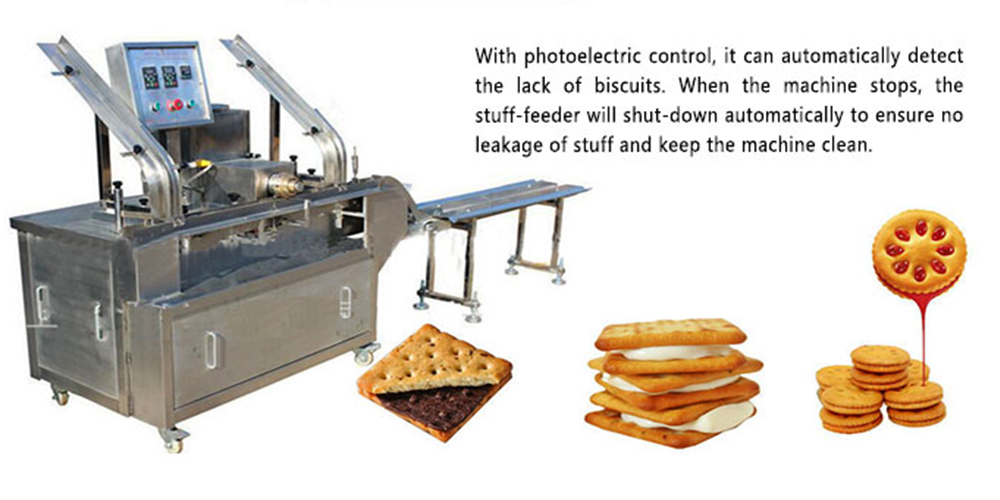

With photoelectric control, it can automatically detect the lack of biscuits.

Product description

Adjusted by advanced step less transducer, the speed is stable.

*With photoelectric control, it can automatically detect the lack of biscuits. When the machine stops, the stuff-feeder will shut-down automatically to ensure no leakage of stuff and keep the machine clean.

*Arranged by the star-wheels, the biscuits are ranked orderly.

*The temperature can be controlled automatically to ensure constant temperature for the stuffing, when various specifications of layer-biscuit such as rectangle, square, roundness and ellipse are changed, every parts can be adjusted rapidly and easily.

With novel aspect, the whole machine is mainly made of stainless steel and meets the foodstuff sanitation requirement.

Features:

*Adopts advanced stepless frequency conversion for stable speed.

*Photoelectric control automatically detects low-fill biscuit filling. When the machine stops, the feeder automatically shuts off to prevent leaks and keep the machine clean.

*Star wheel arrangement ensures neat biscuit arrangement.

*Automatic temperature control ensures a constant filling temperature. When changing biscuit layers of various sizes, including rectangular, square, round, and oval, all components can be quickly and easily adjusted.

*Stylish appearance. The entire machine is primarily constructed of stainless steel, meeting food hygiene requirements.

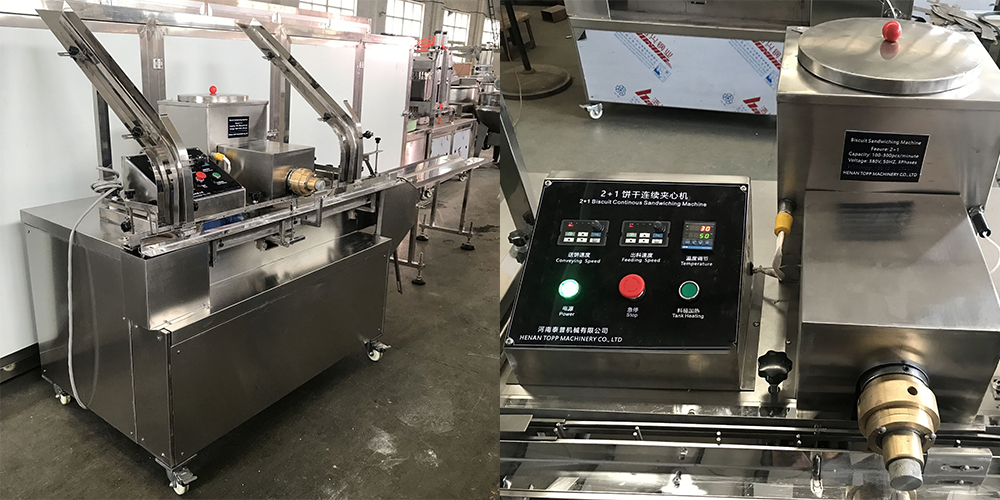

Product parameter

Model | TPP-D |

Function | One-row, one-layer two/one-color butter/jam stuffing |

Producing capacity | 100-300piece/min |

Working power | 220V 50Hz(60HZ) |

Power of the machine | 2.5KW |

Specification of stuffing | (Roundness):(ø)30-60(mm)(H)3-8(mm) |

Overall size | 3300*1200*1500 |

Product picture